To meet and exceed military requirements for eyewear, the science behind a product must be absolutely exceptional. CTRL® eyewear is now on the U.S. Army APEL list. Here’s how we got there:

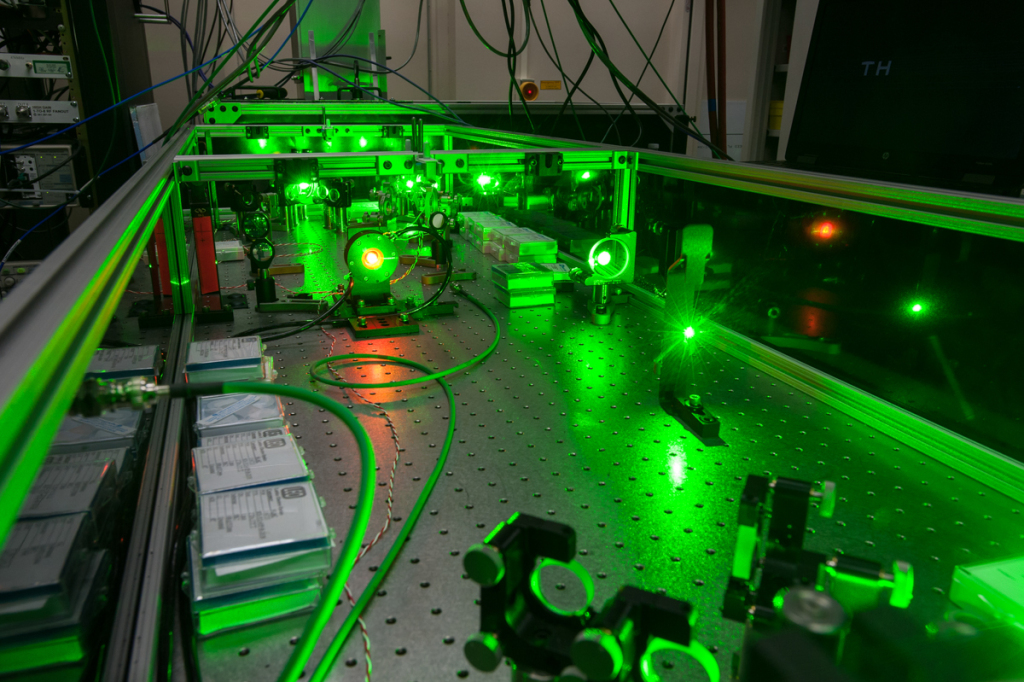

Every CTRL® product benefits from over two decades of scientific research. Unlocking the untapped potential of liquid crystals to deliver electronically-controlled instantaneous color switching was the key.

The world-renowned scientists and engineers at AlphaMicron set to the task. Research and development took place across chemistry, material analytics and electronics labs, as well as manufacturing, testing and quality control spaces.

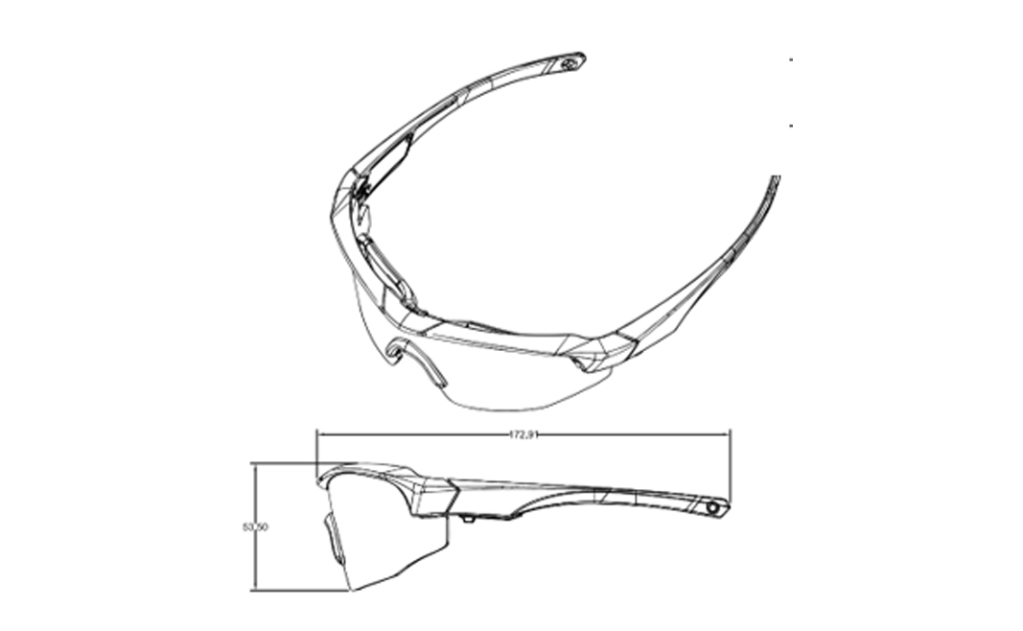

Finally, we were able to crack the age-old problem of how to place the liquid crystals that delivered this tint-changing technology on flexible plastic lenses for personal use. By curving those lenses, the world’s fastest-changing tint technology could now be used in visors, goggles and other eyewear for the first time.

Groundbreaking? Yes.

Life saving? Absolutely.

e-Tint® performance has undergone rigorous testing of its advanced electronics materials and systems. The electronics are designed to minimize power consumption while maximizing the longevity of the device. All testing has been completed at AlphaMicron’s labs in Ohio.

After extensive scientific and development to minimize power consumption and maximize longevity, we work with industry leaders to create designs that meet every requirement. From function to fashion, our aim is to deliver unprecedented performance in sleek, rugged styles.

All materials, system parameters, and electronics are developed from scratch in-house, further tailored to individual product needs.

This approach sets us apart – and it sets us ahead.

From custom-made materials or chemicals to our proprietary and patented manufacturing techniques, the results speak for themselves: our state-of-the-art products are widely recognized to be light-years ahead of the competition.

For a product to be successful, it must meet its designed requirements consistently.

For military safety items, this is non-negotiable and often a matter of life or death. To achieve this, our testing facilities have been Army-Certified, to ensure that we provide our customers with the highest quality materials and workmanship, without exception.

Our facilities are ISO 9001-2015 compliant.

What will be next? Bluetooth controlled active sensing and laser protection, for starters. Prepare for a new generation of ultra-fast light-reactive eyewear capable of providing never-seen-before adjustable laser protection. This innovation will provide active eye protection against laser and intense flashlight (including IR radiation), with our signature ultrafast (faster than 0.01 sec) switching time.

Note: Customers in Europe are liable for VAT.